There's a few different types of 3D printers, but The3DPrintingMan use exclusively FDM or Fused Deposition Modeling machines. This means that our machines make items by fusing later after later of plastic together until a finished item is created.

In more detail, we feel our printers a roll of precisely measured plastic. Each machine takes the plastic and melts it to over 200 degrees Celsius or over 400 degrees Fahrenheit! For each layer, the plastic is then forced through a nozzle with an open that's a fraction of a millimeter wide. The nozzle then move front to back and left to right on the plane, using a motor and gear (the extruder) to place plastic in the exact right places.

Once a layer is complete, the glass bed moves down a fraction of a millimeter and the process repeats over and over again. Some items have over 1000 layers of plastic! Each layer of plastic is smooshed into the one before it when the melted plastic comes out of the nozzle, creating a single object from a lot of layers of plastic, remarkable similar to how layers of brick are combined to form a wall.

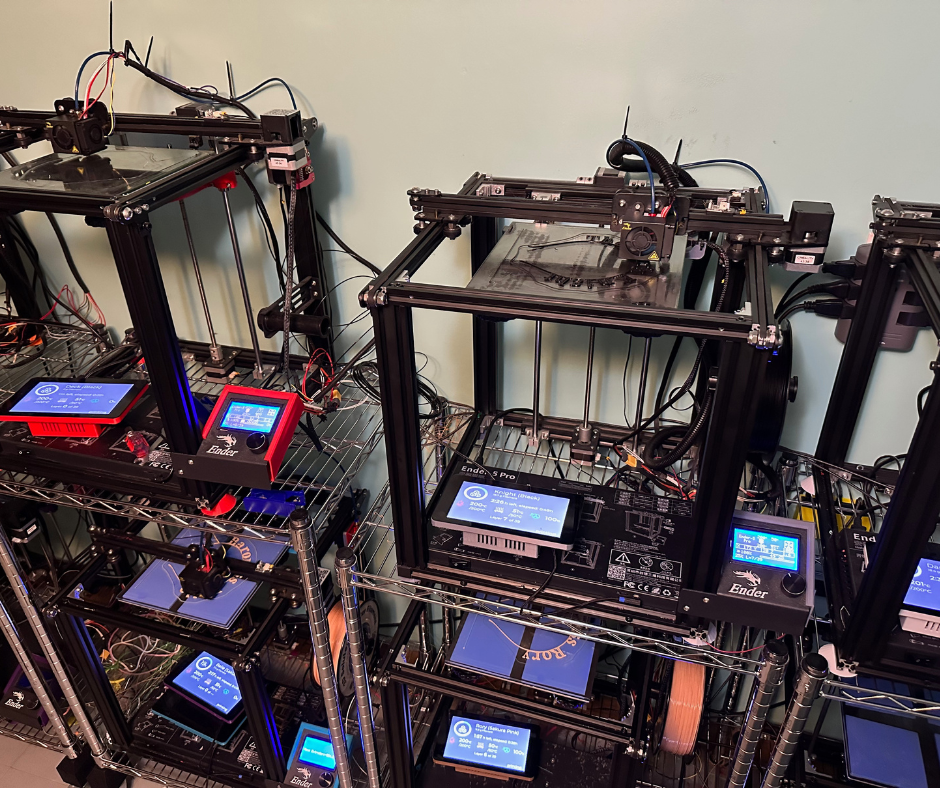

Below is a time lapse of a 3D printed pet bowl. The one cup bowl shown below usually takes about 10-12 hours to make! How amazing is technology!